|

|

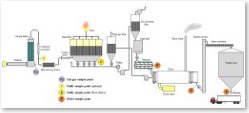

| Carbon Black Manufacturing & Operation, Equipment & design |

|

The major focus, besides the technical and organizational excellence, due to this highly competitive business, is directed towards improving the equipment conversion efficiency, reliability and simplicity with state of the art design and equipment manufacturing

LARGE PORTFOLIO OF EQUIPMENT FOR MOST OF THE CARBON BLACKS GRADES AND SEGMENTS

ASTM (Hard/Soft), SPECIALTY (COLOR, PLASTICS, MRG, CONDUCTIVE GRADES) |

|

LIST OF EQUIPMENT INCLUDED

- COMBUSTORS (modern design, balance axial flow up to 2200 °C flame temperature). Fuel options, Natural Gas, SFS or COG.

- CHOKES (All metal water cool, up to 2200 °C combustor temperature)

- REACTORS (ASTM/SPECIALTY) 6000 Nm3/h to 25,000 Nm3/h process air flow per reactor

- AIR PRE-HEATERS (APH) from 700°C to 930°C pre-heated air temperatures

- APH STEAM CLEANER (SOOT BLOWER). Matching APHs

- APH INLET BOX (PLENUM) Matching APHs

- OIL PRE-HEATER (OPH). Single or dual (Make oil + SFS) in a single unit. Up 350°C make oil temperature. Temperature control and automatic cleaning system for optimum performance

- REACTOR/VENT SCRUBBER THREE WAYS VALVE

- VENTURI COOLER. Most efficient, economical and simplest water evaporator device

- PRIMARY BAG FILTER (PRIMARY BAG COLLECTOR). Modern design with inlet diffusor/smoke gas distribution and square section for minimum carbon black build up. Special non corrosive alloys

- ROTARY AIR LOCKS (RAL) 8” and 16” matching all filters and other equipment

- AIR CONVEYING FILTER (DENSE BAG COLLECTOR). Modern pulse jet top entry design with inlet baffles for optimum performance

- DRYER FILTER (VAPOR BAGS COLLECTOR) for optimum performance Modern pulse jet top entry design with inlet baffles

- DEDUSTING FILTER

- SURGE TANK (AGITATOR TANK), Modern flat bottom with continuous level control

- CARBON BLACK FEEDER (HIGH SPEED FEEDER). Three sizes from 10 to 35 L/m capacity

- PELLETIZERS. High performance, low maintenance cost. 20”, 30”, 36” and 45” sizes. Capacity 30 t/h to 180 t/h CB capacity per unit. Hot water or steam heated

- DRYER INLET CHUTE. Hot water or steam heated

- SPECIALTY ITEMS, TRANSITIONS, HIGH PERFORMANCE NOZZLES, LANCES, GUNS, AND AUXILIARY EQUIPMENT, FLAPPER VALVES, etc.

|

We will be glad to discuss and make a proposal of customized equipment according to your requirements without any compromise from your side |

|

The Carbon Black equipment will be manufactured in India by SHIVAM SUNDARAM CARBON PRODUCTS PVT LTD (SSCP) under the license, support and guidance from CARBON BLACK TECHNOLOGY S.C.

|

|

|